electrical discharge machining adalah

The Basics of Electrical Discharge Machining EDM Wire Cutting Electrical Discharge Machining. Electrical discharge machining tends to work to very tight tolerances of - 0012mm.

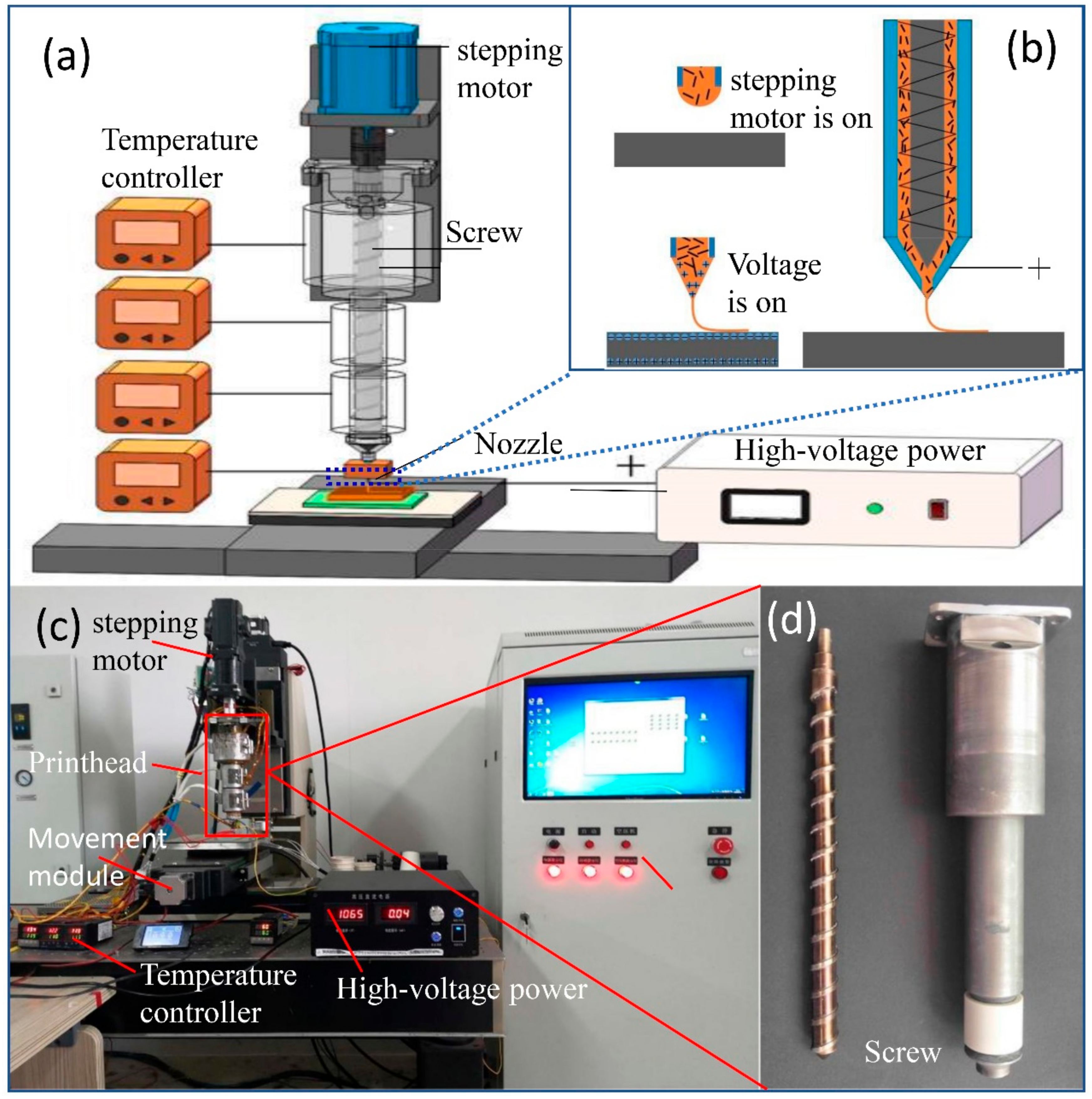

Micromachines Free Full Text The Electric Field Driven Fusion Jetting 3d Printing For Fabricating High Resolution Polylactic Acid Multi Walled Carbon Nanotube Composite Micro Scale Structures Html

Electrical discharge machining is an effective manufacturing solution for machining applications with high requirements.

. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated. Ad General Manufacturing LLC Delivers High-Quality Products To A Variety Of Industries. EDM is especially well-suited for cutting intricate contours or.

Our Services Include CNC Machining Grinding Milling EDM Wire Water Jet Cutting More. Asal mula EDM Electrical Discharge Machining adalah pada tahun 1770 ketika ilmuwan Inggris Joseph Priestly menemukan efek erosi dari percikan arus listrik. For this type of EDM a wire is used as an electrode and is continuously.

Ad For Precise Machining and Remarkable Surface Finish. Kesimpulan EDM Electrical Discharge Machining atau Pemesinan Energi Listrik adalah suatu metode pemesinan yang pada dasarnya digunakan untuk logam keras atau logam-logam yang tidak mungkin dapat diolah dengan menggunakan. Electrical Discharge Machines in Piscataway NJ.

Debois Energy Services Inc. Strong easy to machine great surface finish isomolded graphite. Electrical Discharge Machining AdalahElectrical Discharge Machining EDM adalah non-conventional machining process.

Asal mula EDM Electrical Discharge Machining adalah pada tahun 1770 ketika ilmuan Inggris Joseph Priestly menemukan efek erosi dari percikan arus listrik. Ad Full suite of CNC machining services including the latest in wire EDM machining. Name A - Z Sponsored Links.

Asal mula edm electrical discharge machining adalah pada tahun 1770 ketika ilmuan inggris joseph priestly menemukan efek erosi dari percikan arus listrik. Holes in the air brakes or Pneumatic Brakes were done by an electrical discharge machining process. Electrical Discharge Machining EDM is a method for producing holes and slots or other shapes.

It is used for producing hole size less than 01 mm. Here are some applications of Electrical Discharge Machining. Dua proses utama yang.

For quality parts delivered on time choose Xometry cnc machining services. Electric discharge machining EDM is the removal of materials conducting electricity by an electrical discharge between two electrodes Workpiece and tool a dielectric. Used for die sinking or die manufacturing.

This is a significant characteristic that makes it applicable in the aerospace and medical industries. Asal mula EDM Electrical Discharge Machining adalah pada tahun 1770 ketika ilmuwan Inggris Joseph Priestly menemukan efek erosi dari percikan arus listrik. It is also called spark erosion.

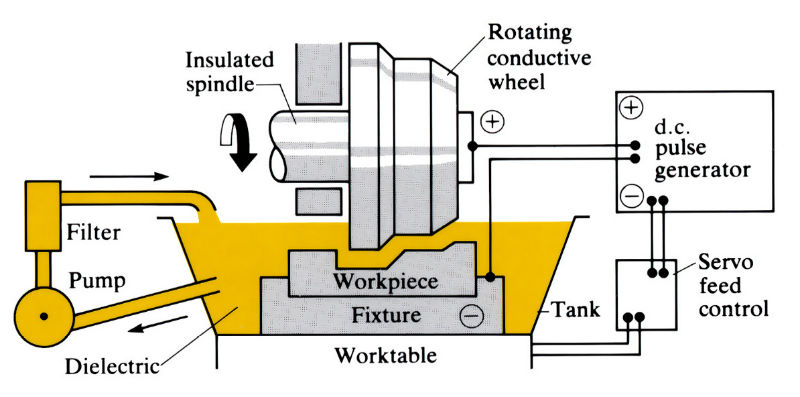

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Electrical Discharge Machining Itu Apa Sih Pt Indonesia Surya Sejahtera

Pudak Scientific Aerospace And Precision Part Machining

Pdf Die Sinking Edm Process Parameters A Review

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Ch 26 Abrasive Machining And Finishing Operations Brenton

Cnc Wire Cut Edm A And Experimental Set Up B Download Scientific Diagram

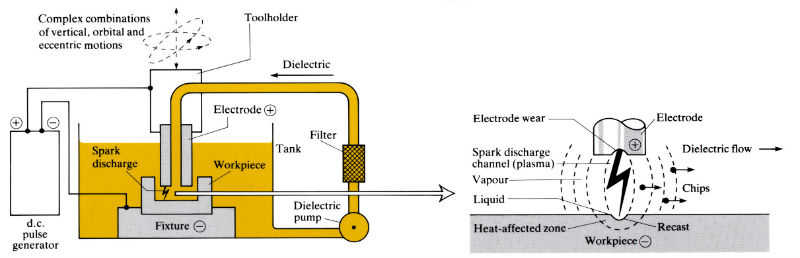

Mechanical Engineering Electrical Discharge Machining Edm Principles

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Edm Notches Custom Applications Top Notch Edm Services

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Schematic Diagram Of Electric Arc Discharge Apparatus Download Scientific Diagram

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Edm For Injection Mold Building Basilius Inc

Mechanical Engineering Electrical Discharge Machining Edm Principles

Gambaran Singkat Edm Hari Pernanda Lukman Academia Edu

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University